Disposable chopsticks are a dime a dozen in Singapore, but company ChopValue turns them into elegant furniture, recycling over a hundred million.

Disposable chopsticks can be found anywhere and everywhere in Singapore. From noodle restaurants to your dabao (takeaway) containers, it’s hard to go one day without coming across a single pair of disposable chopsticks.

You might think that just because it is made out of wood, you can recycle it easily, but the oily food stains that coat the surface make this a harder process. According to NEA, disposable chopsticks are not recyclable or are to be thrown in the recycling blue bins. Instead, these utensils are supposed to be disposed of as general waste alongside your other trash.

This is where Chopvalue comes in.

more on Chopvalue.

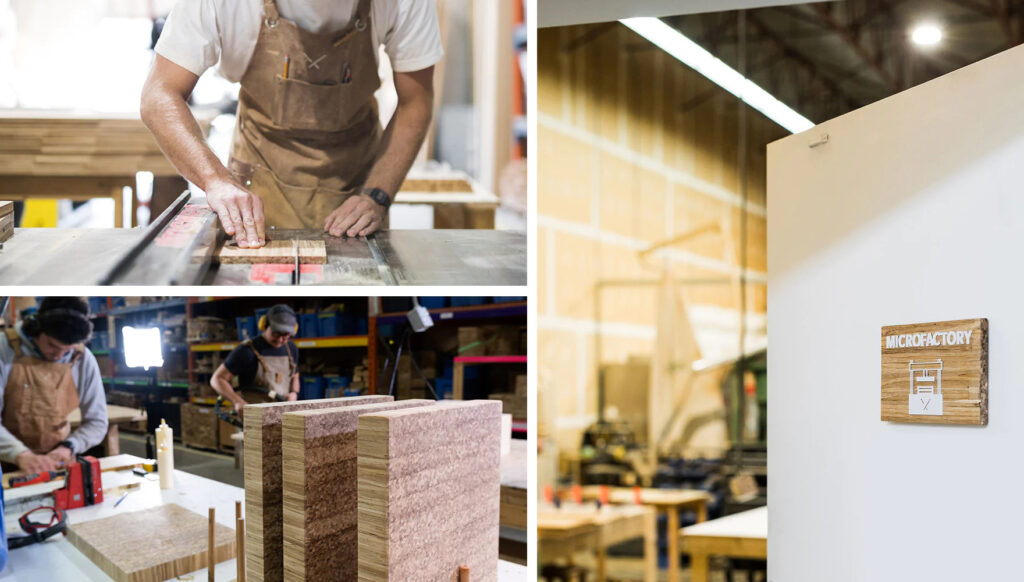

Initially founded in Vancouver in 2016, ChopValue was created in an attempt to tackle the wood and construction waste in the area. The company has since opened a Microfactory here in Singapore in 2021, in which approximately 10 million chopsticks have been recycled. They have also collaborated with over 1,700 community restaurant partners. In fact, ChopValue has just announced its partnership with the shopping mall Waterway Point just this month.

As the first circular economy franchise in Singapore and across the globe, its presence in the market is symbolic of a turning point in conversations regarding the reduction of carbon emissions locally and worldwide. With the Singapore Green Plan 2030 of achieving net zero emissions by 2050 in the background, it’s no doubt that the presence of such a company is gladly welcome.

circular economy with chopsticks?

In 2019, over 100 billion tonnes of material had been extracted and used by the global take-make-waste economy, with over 90% of all materials being extracted and used being ultimately wasted in the end. This places a significant strain on the Earth’s limited resources, especially considering the time required to generate some of these resources. This is also what makes the circular economy a much more sustainable production and consumption model that all should strive towards.

By having raw materials kept longer in production cycles and used repeatedly or in multiple ways (such as ChopValue’s method of upcycling disposable chopsticks into durable furniture!), much less waste is generated, while simultaneously alleviating the strain put on Earth.

ChopValue’s one-of-a-kind, environmentally-friendly approach.

How does the process go? ChopValue utilises an “urban harvesting” approach, sourcing chopsticks from local businesses, restaurants, shopping malls, and many more. They are then sorted and processed locally before being turned into a high-performance material, made entirely out of disposable chopsticks. The last step of the process involves product manufacturing and turning this material into elegant and minimalistic products meant for the home and the office.

According to the 2021 Urban Impact Report released by ChopValue, the company has made sure to keep its environmental impact to a minimum. They have a zero-waste approach to manufacturing – by either making sure waste and cut-offs are being saved and reused in the production of smaller products or that any sawdust generated from sanding down products are being repurposed as a wood filler. Oils and resin used in the making of products are also environmentally friendly and free of any toxic chemicals. Lastly, all products are packaged with biodegradable, starch-based peanuts and recycled paper is used in wraps, cards and labels.

With ChopValue, they’re embodying ‘Every small step and action counts’. Even the seemingly trivial chopstick can add up to something much, much more: ChopValue has managed to transform over 100 million chopsticks into new products (the equivalent of at least 136,000kg of carbon), as well as closed a USD $7.7 million funding round meant to expand its Microfactory network.

extra funding = bigger growth = more chopsticks recycled.

The funding round was done with the aim of further expanding into the Asia Pacific and European regions. Those involved were from varied backgrounds: two high-profile technology entrepreneurs with expansion interests in Asia Pacific and Europe, corporate venture capital funds, as well as existing investors.

Funds raised are to better serve any business-to-business operations ChopValue might enter in the future, especially with the aim of expansion and better serving of any B2B partnerships. The main focus would be to increase production capacity and the development of new product lines beyond what they currently offer. Imagine wooden chairs or decorations made out of disposable chopsticks! That, certainly, is a statement piece.

Furthermore, the company has also signed Strategic Growth Agreements for market entries in Japan, Singapore, Central Europe, and the US. Combined with ChopValue’s Microfactory network, this will help allow a more strategic serving of B2B clients while also meeting end-consumer demand simultaneously.

local Microfactories.

ChopValue also aims to invest in research and development, with the goal of optimising its micromanufacturing principles and subsequently ensuring the reduction of its environmental footprint.

Now, what exactly is the decentralised Microfactory approach ChopValue uses? The company expands on the idea of decentralised manufacturing (when goods are made closer to sources of raw materials, but still have to be shipped out for assembly in a separate location) and has its own novel, more environmentally friendly, approach to shipping and manufacturing.

ChopValue focuses on sourcing raw materials (disposable chopsticks, in their case), goods and supplies locally, as well as the distribution of their goods to other local consumers. It aims to establish MicroFactories which can do this in the region and area they are in, empowering local owners and cutting down on both overhead costs and environmental footprint.

CEO and Founder of ChopValue, Felix Böck highlights the company’s “commitment to demonstrating that the circular economy should become the norm when our natural resources are strained, and our landfills continue to grow.”

The “decentralised Microfactory approach that uses local resources for local production to meet local demand will also give a reason to rethink globalised supply chains,” as ChopValue enables small business owners to own local ChopValue franchises – all produced in a local factory.

expanding into other regions.

So by continuing to expand ChopValue’s network of Microfactories, the company is paving the way for a much more sustainable future. Turning what is commonly viewed as “waste” into “resources” helps ensure the company scales responsibly in the future, especially with each Microfactory being tailored to its specific end market size and needs.

With ChopValue looking to announce the opening of an estimated 100 new locations in the near term, this means the company is also hoping to hire a corporate team to boost the demand for the company’s products in the APAC region.

So if you or your office is in the market for some sustainably and locally produced wooden furniture pieces, ChopValue is definitely your best bet for some sharp pieces. Or if you’re on the lookout for where you can possibly upcycle the wooden chopsticks your establishment might have, this would be a great place to start!

Enjoyed this article? Check out the duo protesting fast fashion waste with sustainable, bespoke kimonos or meet the man who never leaves pineapple leaves behind!