Nissan plans to go green with low-CO2 steel and green aluminium for future models. This is in line with the company’s vision for total carbon neutrality.

Nissan recently announced that the company will be planning to use new variants of Kobe Steel for future Nissan models. This will take effect from January 2023, and the steel in question is Kobenable low-CO2 steel, a variant which significantly reduces CO2 emissions in the blast furnace process.

Kobe Steel will also be supplying Nissan with aluminium sheets derived from green aluminium raw materials, and it marks the first time Kobenable Steel will be used in mass-produced vehicles.

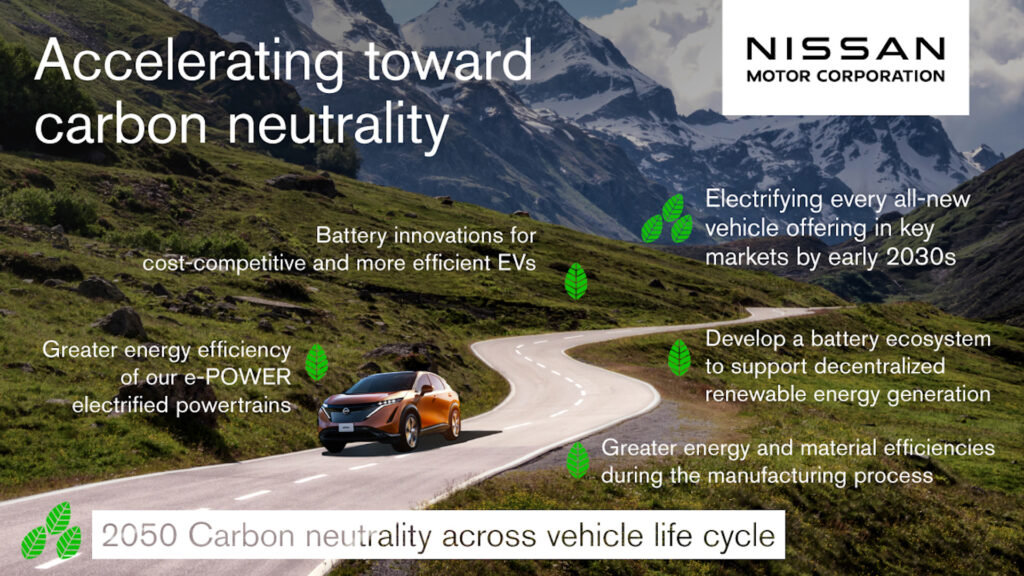

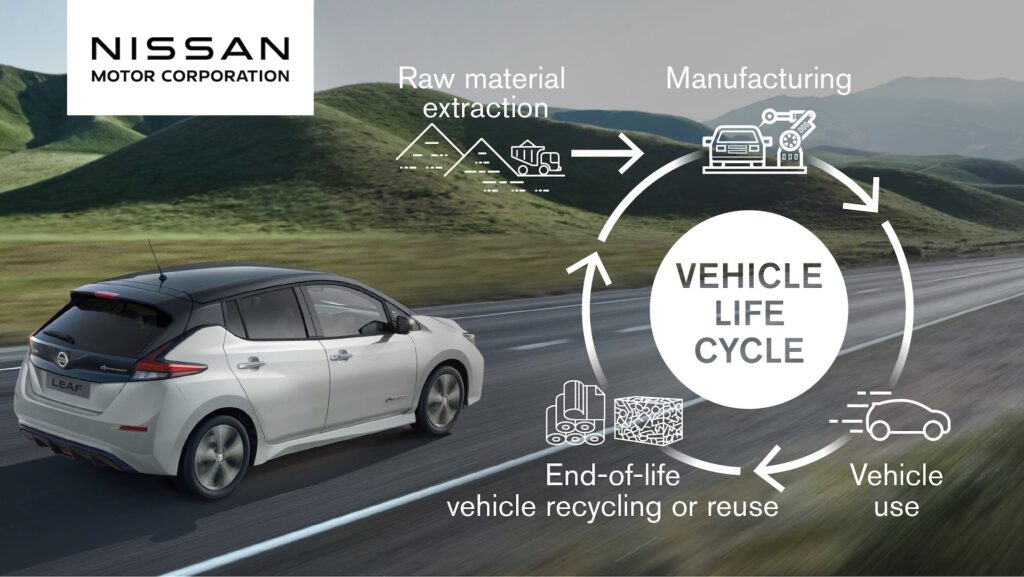

This is another step in Nissan’s plans to achieve total carbon neutrality throughout its products’ entire life cycle by 2050. Since approximately 60% of a vehicle’s weight is comprised of steel parts, with an additional 10% of its weight made up of aluminium parts, the use of low-CO2 steel and green aluminium is a very effective strategy to reduce overall CO2 emissions during parts manufacturing, which is factored into the vehicle’s life cycle.

Future Nissan models will use Kobenable Premier steel, which reduces 100% of CO2 emissions during manufacturing through a process known as mass-balancing. Furthermore, these significant CO2 emission reductions do not compromise the quality of the steel being produced. A win-win for all!

Kobe Steel is also making progress in becoming more sustainable. The green aluminium raw materials purchased to produce these aluminium sheets for Nissan are electrolytically smelted using only electricity generated by solar power, thereby reducing CO2 emissions during aluminium ingot production by approximately 50%. Recycled aluminium materials generated at Nissan’s manufacturing sites will also be used to further reduce CO2 emissions during production.

Both companies will continue their efforts to reduce CO2 emissions, with the aim of realising a carbon-neutral future.

Bentley is also making eco-efforts with their honey bees. Check it out here!